Home Improvement:

The tile substrate starts with a layer of 3/8” plywood

underlayment screwed to the top of the 3/4”

plywood subfloor. There are a ridiculous number of

screws - running every 8” in the plywood with 6” at

the underlayment edges. As usual, Ruby is helping.

NuHeat Warm Floor

Cabling

Warm Tootsies!

One of the many unplanned detours on the project

was the last minute decision to put in electric

heating elements in the thinset below the tile floor.

Although I’m a fan of radiant heating where the

building surfaces radiate heat rather than heating

the air, this was really just to take the edge off winter

mornings on bare feet.

After finishing underlayment, each cabinet is

marked in permanent marker so that the electric

cable can be planned without needlessly heating

underneath cabinets or a refrigerator.

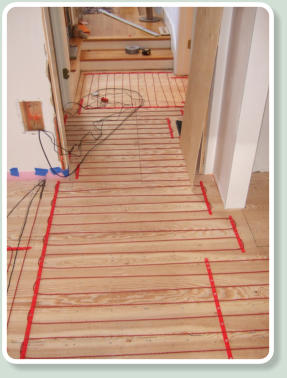

Note how the grid goes to where the toekick will

wind up in the cabinet, but not under the cabinet

itself. The guides have pegs that are pitched at

every inch. So we used a 3” pitch for most of this

floor..

The last bit is finished, but then we found out that

the floor was not at all flat. There was a distinct

ridge in the plywood centered around a basement

lally column. We hadn’t discovered this until the

thinset part was all done. It looked flat, but a 6 foot

straightedge showed that we’d after flatten the floor.

Here, you can see the spool of electric cable that is

run back and forth between the guides. Off the right

side of the picture is the black lead that goes up into

the wall to the floor heating thermostat.

We had enough cable to continue down the hall and

into the hallway half bath. Since you can’t (or are

not supposed to) trim and rejoin the cable, it is

handy to have an area where you can run the cable

long

The finished cable grid is shown below. This was a relatively straightforward process. There is a more popular

option to go with pre-wired thin mats that are thinset-ed into place onto the underlayment. this is both easier and

less expensive for a regular layout like a simple combination of rectangles. However, each rectangle has its own

leads and all of them have to be make it back to a (big) splice at the thermostat. I didn’t like the idea of 5 thick

cables coming up through the wall and the pair of 5-wire splices, so instead I ordered the long cable / guides, and

ran it in the pattern below. The cable has a dead-end at the far side, and the cable actually has both electrical

wires inside so that so that the circuit is formed. Obviously, there is no ability to field-trim the cable

The manufacturer (NuHeat, in this case) supplies

cable guides that can be easily cut and tacked into

place so that the electric grid of cables stays neat

until embedded in thinset mortar

After running the cable and before somebody

breaks it from walking on it, the cable is covered in

either thinset or Self Leveling Compound. We

chose Laticrete 254 latex modified thinset.

Incredibly smooth, sticky, and hard when cured.

Another batch of Laticrete being mixed and troweled

over the wires.

II had a couple of helpers on this one - That’s Ruby

and Joe above