Home Improvement:

Panel Saw

Knowing that it was going to be next-to-impossible to get all that plywood down the stairs to the basement and relatively dangerous to put full sheets through the tablesaw, we set out on New Year’s Day, 2009 to pick up a used panel saw. These make perfect vertical and horizontal cuts. You’ve seen it at Home Depot, I’m sure.Cabinet Parts

Armed with an Excel Spreadsheet with rows for every cabinet and columns calculating the measurements for each plywood part, the sheets are cut down into oversized pieces and labeled. The cuts in each sheet are optimized by using a cutlist program. This saved a lot of wasted wood.Solid Maple Edging

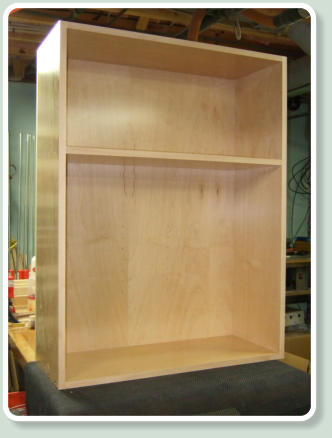

Looking closely at the finished cabinet below, you’ll NOT notice the edges of the plywood. That’s because all plywood edges must be finished with a strip of solid wood to hide the plies. Although there are easier ways to do this (such as that cheesy iron- on veneer), I opted to rout in strip of keyed solid maple.Cabinet Construction

Easy, but requires

planning, discipline and

tools!

If you are even thinking about building your own

cabinets, get this book. Robert Lang’s Complete

Kitchen Cabinet Maker is the reference. Don’t start

buying any tools or wood until you’ve read the whole

thing. It’ll save you so much!

Of course, you might decide to just buy those

cabinets that come in flat boxes instead.

Both the strips and plywood recessed are made on

the shaper using matching cutters that have

reversed patterns from each other. Here we see a

panel attached to a plywood shop-made jig going

through the shaper. You can’t see the cutter, but

you can see the resulting profile on the plywood.

The strips are then glued in.

After curing, a router jig is used to trim the part of

the maple strip that sticks above the plywood face.

The strips are then glued in.

...and clamped

Assembly

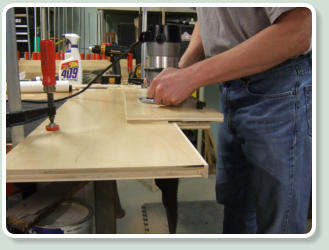

Since consistency is so important, jigs are used everywhere in cabinet construction. For instance, I’m drilling holes in a cabinet side that will ultimately be used to hold up adjustable shelves. It’s OK if the holes are off, as long as it’s consistent with the other side

In this case, the same jig is used for cutting biscuit

slots that will align a stationary top shelf in the

oversized upper wall cabinets.

Consistency!

Sometimes when putting glue in buiscuit slots, you

wind up with too much glue to clean up after

assembly. The Lamello gluing tool made it much

more predictable.

Screws on each side of the biscuit slot apply

clamping pressure to the final assembly.

After a huge amount of planning, CAD modeling, and Excel work, we had 27 sheets of 3/4” prefinished Maple

plywood delivered from Boulter Plywood in Massachusetts. If you own a sailboat in New England, you probably

already know the place.

The idea with the prefinished was that this would cut down on the amount of spray finishing to do after assembly.

It was mostly a good choice, but scratches from running the wood through the shop are not easily fixable.