Home Improvement:

Large-Format Tile

Floor

FInally after flattening the floor, we are able to put

down the Ditra crack-isolation membrane and 12 X

24 inch floor tiles. Because the tiles are so large, I

was worried about “lippage” - where a tile is

noticably higher than an adjacent tile. To eliminate

that, we used something called the “Tuscan

Leveling System”.

The Tuscan Leveling System pieces are seen here.

There’s a white plastic “T-strap” and a red plastic

reusable cap that are put on with a special tool to

create a tension that pulls adjacent tiles into vertical

alignment.

...and into the half-bath. Note the threshold of cut

tile that makes the pattern centered in the bath.

One of the joints running with the threshold will be a

“soft joint” of matching caulk instead of grout so that

the floor can have some minor movement without

cracking.

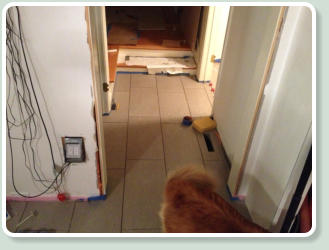

Hasty escape by Ruby over the ungrouted tile floor

down the hall...

First step is to put down the Ditra from Schluter Systems. This crack-isolation membrane works by forming

columns of mortar that support the tile, but allow some small amount of lateral movement so that the tile doesn’t

crack when the floor underneath shifts.

Installation is as simple as cutting with a utility knife, embedding in a fresh layer of thinset, and then rolling it with

a rental linoleum roller makes it pretty foolproof.

To the left, you can see one of the right angle floor

lasers that we used to maintain consistent joints

down the hallway and across the whole kitchen.

These right angle lasers are an absolute must have

for DIY tiling.

Above is the hallway half-bath after fitting in all

those tiles that Joe (Shown standing in the left

picture) had cut and labeled. Two people made this

way less tedious.

Next step is grouting and we had selected a

cementitious dark grout made by Tec. Above is how

it looked before removing the residue in the final

wash. The result was blotchy. There were areas

that were practically white. Maybe I washed the

pigment particles out?

If you tension too hard, the strap breaks, so it takes

a certain amount of getting used to .

Whatever was the cause, it was unacceptable. We

ripped it all out in a few hours with a Fein

multimaster. It’s painful to undo progress, but it was

a great move.

Instead, we decided to go with an epoxy grout from

Laticrete called Spectralock. In this picture, I’m

mixing all of the needed powder parts together in

order to get complete color uniformity across all of

the batches. Then I’ll scoop them back into the

cartons while weighing to be sure that I have

consistent results.

Each of these cartons must be added to a another

coupld of liquids to make a taffy-like grout that

needs to be forced into the joints.

Once mixed, you get about 20 minutes to use the

grout as it is on a one-way trip to hardening. Mixing

it periodically does nothing to elongate the working

time like it would with cement-based grout.

This is really hard work!

After an initial washing and cure, we used a floor

machine (handy!) to scrub the last traces of epoxy

from the tile faces.

The hard work pays off with perfect results and no detectable transition between batches. I could do abut

50 square feet a night and the resulting floor looks as if done professionally in one shot. The fact that we

have a stain-proof kitchen floor is a bonus.

I don’t know why I didn;’t take any pictures of putting the Ditra down, although it was particularly exciting.

We used a non-modified mortar since plywood bonding is not needed. The 75 pound linoleum roller is in

the foreground and it made a real difference in getting full contact of the fleece lining of the Ditra into the

fresh mortar.

We had evaluated several alternative patterns and orientations for the 12 by 24 inch tile. In the end, we

decided that the “staggered” approach in the bottom right picture above was the best. If we put it down

across the width of the kitchen, it magically lined up with the two aisles on either side of the island.