Home Improvement:

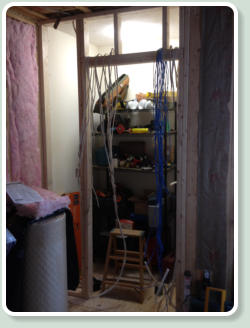

Here’s an example. On the left is the back of the

dining room drywall and straight ahead if the back of

the family room. The big black pipe is a soil pipe to

the upstairs bathroom. It used to be ABS - the

lightest and loudest to code in this area. Gutting the

room meant that we could replace that section with

cast iron and quiet down those upstairs toilet

flushes. Installing insulation everywhere around the

room also cuts the noise transmission. And finally,

we found some interesting ways where air coming

through the recessed lighting could (easily) pass

through to a vented attic above part of the kitchen.

This is the chance to properly air seal everything - at

least in this room.

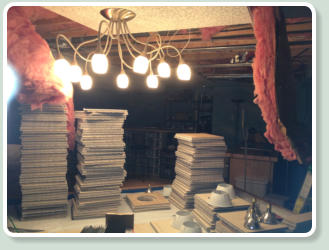

This is much of the drop ceiling in the basement that

needed to come down in order to make the

plumbing and electrical changes for the kitchen. We

needed a few more circuits, another sink supply and

drain, and plenty of other cat-6 and audio cabling.

Note the piece of subfloor cut out. This was to get

access to a pipe that used to have the refrigerator

ice maker tapped off of it. The Fein Multimaster lets

you plunge cut like this and replace the same

plywood back with some extra joist work.

Inside the Walls

Gutted!

Once you rip down the drywall and plaster at the

beginning of a rehab, you’re struck by how

advantageous it is to do any wiring and insulation

and air sealing at the same time.

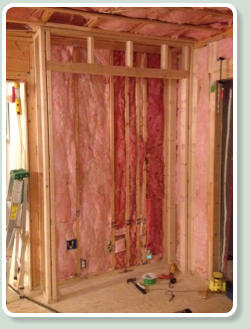

Here’s a wall behind a future sink location. We put

in a new drain/vent as well as ran the supply using

Pex. The horizontal outlets are in the future

backsplash

One corner of the refrigerator nook opened to a

ductwork chase adjacent to the Living room. This

was the chance to run some extra cat6 cables to the

living room. Using baluns, we can pipe the high def

video from the living room to the kitchen TV.

What was an alcove, was framed into a pantry.

During construction, this was also the tool closet.

Very convenient!

.And since we had access to the dining, room, we

could run audio to a new pair of in-wall speakers.

You can see the effect in the background of this

picture. The framing in the picture at left forms the

continuation of the hallway into the kitchen. Then

the Sapele surround for the fridge is only 12” deep

and winds up looking like a big shallow pantry.

Without drywall, we suddenly had at least some access to inside the walls of our laundry room, stairway, half-bath,

living room, dining room and family room, and a bathroom and bedroom upstairs. Now was clearly the time to wire

for whole-house audio, make electrical and plumbing changes, etc

In this corner, we framed out a new wall that visually

makes the refrigerator have 13” less depth.

All walls and ceiling were insulated in order to cut

down noise transmission to adjoining rooms.

This is a handy device for one-person drywall

hanging. Usually available on sale at Harbor

Freight for $200.

ITime to drywall. In this case we want to use veneer

plaster and so this is “blueboard” which has special

multiple paper surfaces to bond with the plaster without

drawing too much moisture and weakening the plaster..

The one thing that I farmed out was the plastering. I

really wanted to learn this since I’m a pretty good

slim-coater, but my first experiment made it clear

that I’d need a few days practice to get something

acceptable. Instead, I spent the money, went on a

short business trip, and came back to this

perfection.

Tough to see in this terrible camera phone picture, but

every joint in the drywall was caulked for air sealing

before the taping and plastering. electrical boxes were

taped with Siga Rissan tape inside the walls (not in the

box) where wires come out. And the place in the

ceiling where there’s a transition to an attic was

detailed with spray foam to disallow air from the inside

to that attic.