|

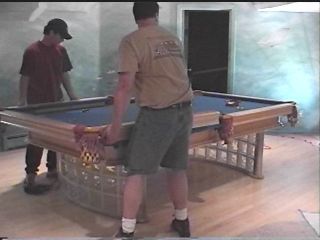

Things were a little chaotic at first, but we

figured out exactly where the pedestals looked best on the frame, and

started assembling the glue blocks and plywood that formed the mounting

point for the table. On the right is Greg, one of the installers

from Recreation World. |

|

|

|

We set the frame on the pedestal and gave it

a rough leveling by shimming under the legs. Next, we need to

predrill and install a 6" lag screw through the frame and securely

into each of the four maple (covered in aluminum) legs on the glass block

pedistal. |

|

We needed to cut small notches on the top of

the frame to run the drill through. Each hole (and therefore

lag screw) is on a slight angle to catch the middle of the leg properly. |

|

After the hole was drilled, I used a forstner

bit to create a flat surface perpendicular to the hole for the washer to

bear down on. Details, details... |

|

Lag screw in place... |

|

An air-ratchet moves things along quicker. |

|

The finished screw. Four more, and the

table is going nowhere.

Now for the slate! |

|

Kevin and Greg lower the 1" thick

"Original Italian Slate" onto the frame. The slate comes

in three sections and is screwed into the frame at assembly time. |

|

Notice the extremely sensitive Starrett

machinist level (on table at left) that is used to verify that everything

is level. Imagine, a tool that I don't have... Just a question

of time, I think. |

|

The slate sections are then seamed together

in a most clever way. Melted beeswax is poured in place and allowed

to dry in only two minutes. |

|

The extra wax is then scraped off

completely flush. The resulting seams cannot be felt under the felt

even if you know where they are! |

|

Things are really coming along now. The

Simonis felt is tacked along one end to the strips of wood that come

already glued to the bottom of the slate... |

|

...And then stretched / tacked on the other

end. By the time the sides are stapled, the felt is wrinkle free and

tight. |

|

Then the pockets get some extra cuts /

staples. |

|

Next the rails, aprons, and pockets - already

assembled into two pieces - are joined together and bolted securely to the

table. |

|

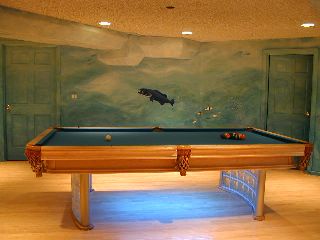

Voila' |

|

The new pockets from RCDesigns were the final

step. |