|

This is the curved landing in its finished

state. Notice the curved wooden riser and the fact that the edge

overhang is a perfectly smooth round over with no end grain showing.

There's actually a "nosing" installed at the end of all those

floor boards. |

|

It starts with a basic platform that will

support the weight of the entire lower staircase and form a solid mount

for the newel and balustrade. |

|

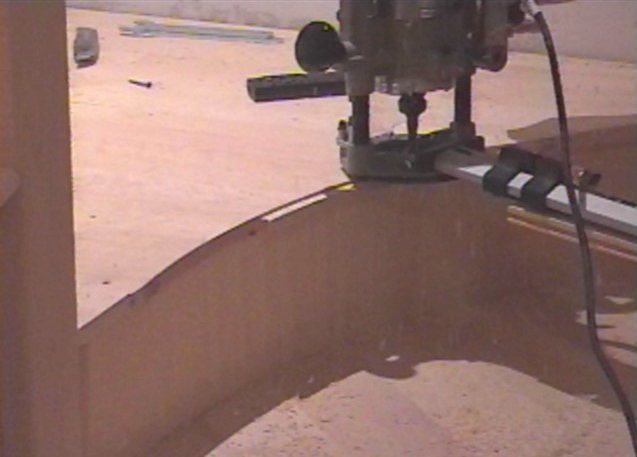

To create the curved subfloor to top the

platform, I am cutting the edge using a router mounted to a 36"

compass arm. This technique was used in many places around Atlantis,

and we'll see it in use again later on in this page. |

|

Here's the platform waiting for the curved

wooden riser. |

|

I had no idea how we were going to do this,

but Brenda found this plywood at a local lumber yard called "Wacky

Wood". This stuff bends so easily, that we rolled the 4X8 sheet

into a large tube to get it home. In the piece at left, it is

curving under its own weight. The thickness is 3/8", so I used

two thicknesses to form the riser. |

|

...Nailing the riser in before the flooring

goes in... |

|

And we're done. I used many

nails at the extreme top and bottom of riser. The nails at the top

are hidden by the flooring overhang... |

|

...And the nails at the bottom are covered by

flooring. |

|

Now the platform is floored and roughly cut

at its ends for the curve. |

|

Here's that routing technique again.

The platform that forms the anchor for the compass pivot is nailed into

the freshly laid floor, but all nail holes will disappear before

finishing. |

|

The first couple of passes are used to cut a

smooth curve. |

|

The last pass was used to cut a groove (as in

"tongue and groove") into the end-grain of the flooring that

will receive the curved, tongued, nosing. |

|

This is the platform before the nosing

installation. (Click for enlargement) |

|

and here is the nosing. Take a good

look at this. It is 3/4" thick, and about 1" deep.

The 1/4" on the left side is a segmented tongue that will fit into the grooved platform

flooring. The other side is a complete bullnose rounding. The

entire five foot length is curved on a 36" radius. This thing

deserves its own web page, but I have no additional images of how I made

it. Here's the synopsis: Cut the tongue into the edge of a 6" board

and segment it. Rip the board so that only the tongued 1"

section remains. The difficulty now is running such a thin board

through a shaper to put the bullnose on. The secret is to use a

grooved carrier board to hold the tongue as it goes through the shaper. |

|

The strip was then bent over the course of a

week by putting it in a flexible pipe full of water and continually

applying bending pressure. It took another week to dry the bent

nosing out enough for the tongue to fit in the groove. Here we are

hammering it in with some glue. From the picture it looks like

I killed a fly in the process. |

|

Starting at the newel and working out, the

nosing looks great as the gap is closed. It took a lot of hammering. |

|

But the result looks effortless. What a

shame I have to point this stuff out. By the way, those two holes at the bottom of the newel where the lag

screws go are shown covered in the newel section. |